Welcome to Our Website !

- SCADA and instrumentation

- Calibration Laboratory

- Coal Gasification

- Material Handling

- Development of Quality Control Equipments

- Substitution of Imported system.

- Fire Ball Chimney Ignition system.

- Governor control system for Hydro electric plant.

Positronics India is now focusing on unconventional energy extraction. These are from:

- Power from Plastic waste using Plasma Technology in collaboration with CSIR, CMERI, Durgapur.

- Power from Solar energy using Salt as energy storage media.

- Power / Fuel from any Carbonaceous waste.

- Catalytic converter to crack Tar and Phenol compound into Lower hydrocarbon based Fuel.

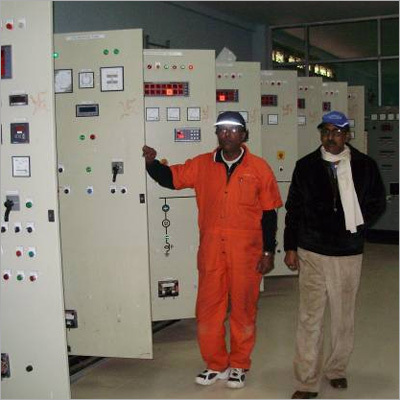

Products Gallery

|

POSITRONICS INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese